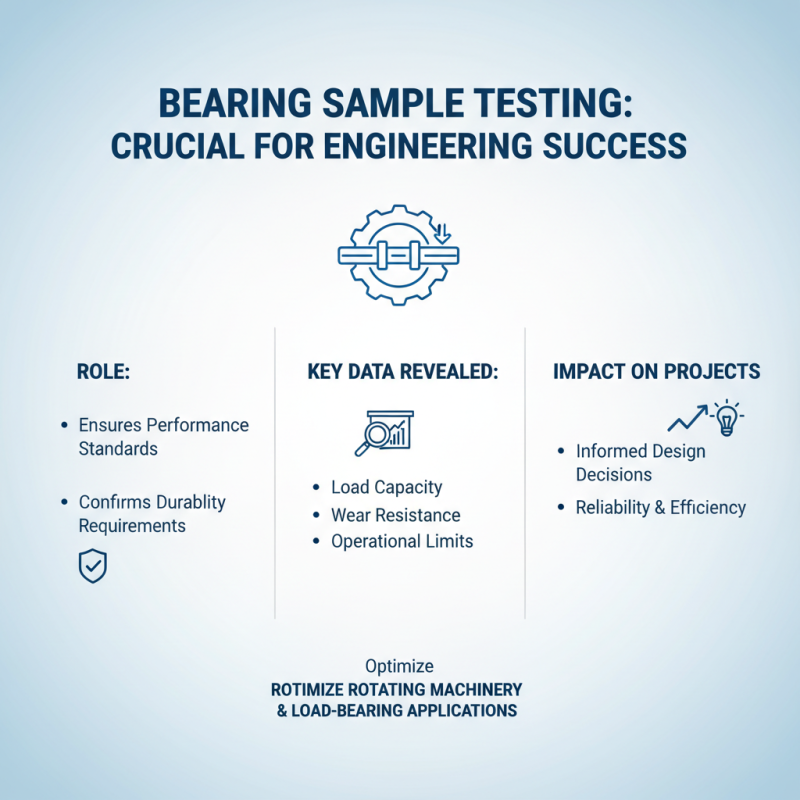

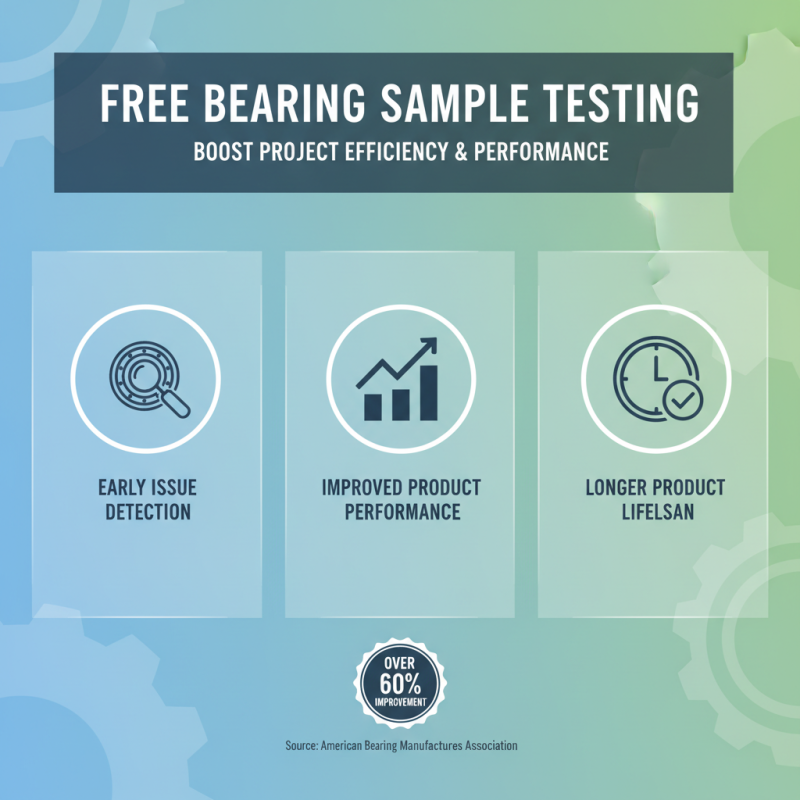

To achieve project success, it’s critical to analyze testing results meticulously. Once you receive your free bearing sample testing services, data collection begins. This data, which may include performance metrics such as load capacity, wear resistance, and temperature tolerances, is fundamental in evaluating whether your project goals are met.

Analyzing these results in a structured manner, possibly through statistical methods or visualization techniques, enables a clearer understanding of the bearings’ characteristics, allowing you to identify areas requiring improvement.

Implementing feedback based on these analyses is equally essential for progress. After identifying strengths and weaknesses in the testing results, the next step involves discussing necessary adjustments with your team or stakeholders.

Whether it’s altering design parameters or refining material choices, integrating feedback ensures that the final product aligns more closely with established project objectives. This iterative process not only enhances the quality of the bearings but also fosters a culture of continuous improvement, which is vital for long-term success in engineering projects.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us