How to Choose CE Certified Bearings for the EU Market Guide

In the intricate landscape of international trade, understanding the nuances of product certification is crucial, particularly in the European Union (EU). Choosing CE Certified Bearings for the EU Market is not merely a regulatory hurdle; it represents a commitment to quality, safety, and customer satisfaction. Expert John Smith, a leading authority in the field of industrial components, emphasizes this point by stating, “The integrity of CE Certified Bearings is paramount for ensuring compliance and building trust in the European marketplace.” His insights underline the significance of these certifications in fostering competitive advantage.

As businesses seek to penetrate the EU market, they must navigate the complexities of regulations that govern product compliance. CE marking serves as a declaration that products meet rigorous EU standards, thereby enhancing their acceptance among consumers and partners alike. The decision-making process for selecting appropriate CE Certified Bearings requires a thorough understanding of both the technical specifications and the compliance criteria essential for successful market entry. This guide aims to illuminate the key factors and considerations in making informed choices that align with the requirements of CE Certified Bearings for the EU Market, ensuring adherence to quality standards while optimizing operational efficiency.

Understanding CE Certification Requirements for Bearings in the EU Market

CE certification is a critical requirement for bearings entering the European Union market. This certification indicates that the product meets EU safety, health, and environmental protection standards. Manufacturers must ensure that their bearings comply with the relevant directives and regulations, such as the Machinery Directive or the Low Voltage Directive, depending on the application of the bearings. Understanding these requirements is essential for any business aiming to market its products in the EU, as non-compliance can lead to penalties, product recalls, or market access denial.

To achieve CE certification, manufacturers must undertake several steps, including product testing, quality control measures, and thorough documentation. This process often involves the assessment of risk to ensure safety and compliance with established standards. It is advisable to consult with notified bodies or certification experts who can provide guidance on the specific requirements for different types of bearings.

Additionally, maintaining clear records and adhering to a reliable quality management system can help streamline the certification process, ensuring that products not only meet EU standards but also are acceptable to potential customers within the market.

Key Standards and Regulations Governing CE Certified Bearings

When selecting CE certified bearings for the EU market, understanding the key standards and regulations that govern their certification is crucial. The primary regulation that applies to these industrial components is the Machinery Directive (2006/42/EC), which sets essential health and safety requirements. This directive ensures that bearings used in machinery are safe and reliable, minimizing risks to both operators and equipment. Compliance with this directive means that the bearings must be rigorously tested and documented by the manufacturer to demonstrate their conformity before entering the EU market.

Another important standard is the EN 620 and EN 606 standards, which provide specifications for the performance and testing of rolling bearings. These standards help ensure that the bearings can withstand various operational conditions, including load, temperature, and speed. Furthermore, adherence to the ISO 9001 quality management standard is often necessary, as it ensures that manufacturers maintain a consistent level of quality throughout their production processes. By rigorously following these regulations and standards, manufacturers can assure their customers of the safety, reliability, and performance of their CE certified bearings in the demanding EU marketplace.

Evaluating Bearing Materials and Their Compliance With CE Standards

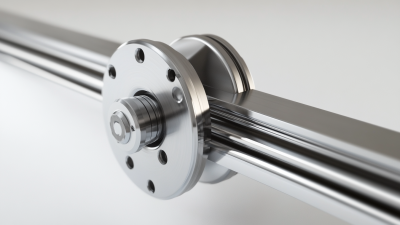

When selecting bearings for the EU market, one of the most crucial factors to consider is the compliance of bearing materials with CE standards. CE certification ensures that products meet safety and environmental protection requirements, which are particularly stringent within the European Union. To evaluate whether the materials used in bearings are compliant, it is essential to examine their chemical composition, mechanical properties, and manufacturing processes. Materials should not only be durable and high-performing but also free from hazardous substances that could pose risks to users or the environment.

Additionally, it is important to assess the testing and certification processes that the bearings undergo prior to being marketed in the EU. Manufacturers should provide documentation that demonstrates adherence to CE standards, including results from mechanical tests, fatigue analysis, and any environmental assessments. This documentation is vital for ensuring that the bearings can perform optimally in their intended applications while maintaining compliance. By focusing on these aspects, buyers can make informed decisions, ensuring that their chosen bearings meet both quality and safety standards required for successful entry into the EU market.

Assessing Performance Metrics for CE Certified Bearings

When selecting CE certified bearings for the EU market, assessing performance metrics is crucial to ensure quality and reliability. Key performance metrics to consider include load capacity, durability, friction levels, and temperature resistance. Understanding these parameters will help you identify bearings that meet the specific demands of your application. Load capacity, for instance, should align with the expected loads under various operational conditions, while durability ensures that the bearings can withstand wear and tear over time.

Tips: Look for detailed technical data sheets that provide insights into material properties and testing standards. It's also beneficial to consult with manufacturers regarding their testing processes and quality assurance practices to gain confidence in the products you choose.

Another essential factor to evaluate is the bearing's friction levels. Low friction is critical for energy efficiency and the longevity of the machinery in which the bearings are used. Additionally, consider the environmental conditions in which the bearings will operate, as temperature resistance can significantly affect performance. By thoroughly assessing these performance metrics, you can make informed choices that adhere to both safety and quality standards essential for the EU market.

Tips: Consider conducting a comparative analysis of different bearing options based on performance metrics and ensure that the selection is well documented to facilitate compliance during audits.

How to Choose CE Certified Bearings for the EU Market Guide - Assessing Performance Metrics for CE Certified Bearings

| Bearing Type |

Load Rating (kN) |

Speed Rating (rpm) |

Material |

Application |

CE Certification Year |

| Deep Groove Ball Bearing |

40 |

6000 |

Steel |

General Machinery |

2021 |

| Angular Contact Ball Bearing |

60 |

3000 |

Ceramic |

Automotive |

2020 |

| Spherical Roller Bearing |

80 |

1200 |

Bronze |

Construction Equipment |

2022 |

| Tapered Roller Bearing |

100 |

2500 |

Stainless Steel |

Heavy Machinery |

2023 |

| Planetary Gear Bearing |

70 |

1800 |

Composite |

Robotics |

2021 |

Selecting Reliable Suppliers and Manufacturers for CE Certified Bearings

When entering the EU market, selecting reliable suppliers and manufacturers for CE certified bearings is crucial. According to a recent industry report by Grand View Research, the global bearing market size was valued at approximately $79 billion in 2022 and is expected to expand at a CAGR of 4.3% from 2023 to 2030. This growth highlights the importance of ensuring that your bearings not only meet safety and performance standards but also comply with EU regulations, making supplier selection a critical process.

One effective tip for choosing suppliers is to assess their expertise in compliance with CE marking requirements. Look for manufacturers who have a proven track record of producing CE certified products and can provide documentation proving compliance. Additionally, consider their quality management systems; suppliers with ISO 9001 certification demonstrate a commitment to quality assurance, which can greatly reduce the risk of non-compliance.

Another important consideration is the supplier's production capabilities and technology. Suppliers who invest in advanced manufacturing processes typically yield higher quality products that are more likely to meet CE certification requirements. Establishing clear communication with potential suppliers regarding their manufacturing processes can offer insights into their reliability and commitment to excellence.

Engaging in thorough due diligence, such as checking client references and examining previous compliance records, can further ensure the selection of trustworthy suppliers in the dynamic EU market for bearings.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us