Top 10 DIN Standard Bearings Suppliers for Quality and Reliability

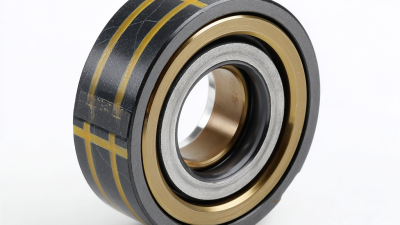

In the ever-evolving landscape of industrial components, the role of bearings cannot be overstated. Among the various types available, DIN standard bearings stand out for their superior quality and consistency, ensuring optimal performance in a multitude of applications. As industries increasingly prioritize reliability and efficiency, selecting a dependable DIN standard bearings supplier becomes crucial to maintain operational excellence. This article delves into the top ten DIN standard bearings suppliers known for their commitment to quality and performance, enabling businesses to make informed decisions in their procurement processes.

Choosing the right DIN standard bearings supplier goes beyond just price comparisons; it encompasses an understanding of product specifications, material standards, and supplier reliability. This discussion aims to highlight the key players in the market who excel in delivering high-quality bearings that meet stringent DIN standards. By focusing on factors such as customer service, technical support, and overall supply chain effectiveness, organizations can find suppliers that align with their operational needs and contribute positively to their bottom line. Join us as we explore the leading suppliers that exemplify quality and reliability in every aspect of their offerings.

Top Criteria for Selecting DIN Standard Bearings Suppliers

When selecting DIN standard bearings suppliers, quality and reliability are paramount. One of the key criteria to consider is the supplier's adherence to international standards and certifications. A reputable supplier should demonstrate compliance with ISO standards, ensuring that their products meet strict quality controls and performance metrics. This not only guarantees the bearings' durability and efficiency but also enhances the credibility of the supplier in the marketplace.

Another vital aspect is the supplier's experience and expertise in the industry. A supplier with a proven track record will likely have a deeper understanding of the specific requirements and challenges related to DIN standard bearings. This experience allows them to offer better technical support, tailored solutions, and insights into the latest innovations in bearing technology. Additionally, customer reviews and case studies can provide valuable information about a supplier's reliability and service performance over time, enabling companies to make informed decisions based on past successes and customer satisfaction levels.

Top 10 DIN Standard Bearings Suppliers - Quality and Reliability Metrics

Overview of DIN Standards in Bearing Manufacturing

DIN standards, established by the German Institute for Standardization, play a crucial role in the manufacturing of bearings. These standards provide a comprehensive framework that ensures consistency, quality, and reliability in bearing production. By adhering to DIN specifications, manufacturers can offer products that not only meet the stringent requirements of various industries but also ensure interoperability between different components. The standards cover various aspects such as dimensional accuracy, material quality, and performance characteristics, making them essential for applications in automotive, aerospace, and industrial machinery sectors.

Incorporating DIN standards into the bearing manufacturing process allows suppliers to enhance their credibility and trustworthiness. Customers can rely on these standardized products, knowing they have undergone rigorous testing and quality checks. Furthermore, DIN standards encourage continuous improvement and innovation within the manufacturing processes, leading to more efficient and durable bearing solutions. By fostering a culture of adherence to these standards, suppliers position themselves as leaders in the market, capable of delivering high-quality, reliable bearings that meet the evolving needs of their customers.

Market Share and Impact of Leading Bearing Suppliers

The global bearing market has witnessed significant growth, driven by the increasing demand for high-quality bearings across various industries such as automotive, aerospace, and industrial machinery. According to a recent market analysis report, the global bearing market was valued at approximately $81.5 billion in 2021 and is projected to reach $107 billion by 2028, growing at a compound annual growth rate (CAGR) of around 4.4%. This growth is largely attributed to the expanding manufacturing sector and advancements in technology, which emphasize the need for durable and reliable components.

Among the leading suppliers in the DIN standard bearings segment, certain companies hold a considerable share, impacting market trends and pricing structures. For instance, recent data indicates that top suppliers command more than 40% of the total market share, highlighting their influence and control over innovations and quality standards in bearing manufacturing. These suppliers not only meet rigorous quality benchmarks but also invest heavily in research and development to enhance product performance and sustainability, ensuring they remain competitive in an evolving market.

Tips: When selecting a supplier for DIN standard bearings, consider not only the product quality but also the supplier’s reputation and market presence. Conducting thorough research on their compliance with international standards can prevent future disruptions in your supply chain. Additionally, staying updated on industry trends through reports can provide insights that aid in negotiating better terms with suppliers.

Quality Assurance Processes in DIN Standard Bearing Production

Quality assurance is a critical component in the production of DIN standard bearings, significantly influencing their reliability and performance in various applications. In the bearing industry, adherence to the DIN (Deutsches Institut für Normung) standards ensures that manufacturers meet stringent specifications for dimensions, tolerance, and material properties. According to industry reports from the International Federation of Robotics, nearly 60% of production downtime in automated systems can be attributed to bearing failures, underscoring the importance of rigorous quality assurance processes in mitigating such risks.

Manufacturers employ a variety of quality assurance techniques throughout the production process. This includes thorough material inspection, precision machining, and regular testing of finished products. Techniques such as non-destructive testing (NDT) and surface roughness measurements ensure that each bearing meets the desired performance criteria. Moreover, a survey by the Society of Manufacturing Engineers indicates that companies implementing advanced quality assurance protocols can reduce their defect rates by up to 50%, thus enhancing customer satisfaction and reducing costs associated with replacements and repairs.

In addition, statistical process control (SPC) is increasingly utilized in the production of DIN standard bearings. By monitoring and controlling manufacturing processes through statistical methods, suppliers can identify potential issues before they lead to defects. A report from the American Society for Quality reveals that organizations using SPC typically experience a 20% increase in product consistency and a 30% reduction in waste, contributing to both operational efficiency and environmental sustainability in bearing production. These quality assurance processes collectively ensure that DIN standard bearings meet the highest standards of quality and reliability, critical for their applications in machinery and automotive industries.

Key Trends Shaping the Future of Bearing Supplier Reliability

The reliability of bearing suppliers is shaped by several key trends that are increasingly influencing the industry landscape. As technology continues to evolve, suppliers are leveraging advanced manufacturing techniques and smart technologies to enhance product quality and performance. Automation in production processes not only improves efficiency but also minimizes human error, leading to more consistent and reliable bearings. Additionally, the integration of IoT (Internet of Things) devices into bearing systems allows for real-time monitoring and predictive maintenance, which further ensures reliability and longevity of components.

Sustainability has emerged as another significant factor affecting supplier reliability. Modern consumers are more environmentally conscious, prompting suppliers to adopt sustainable practices in their operations. This includes utilizing eco-friendly materials and reducing waste during production. Suppliers that prioritize sustainability are likely to build stronger relationships with clients, as businesses increasingly seek partners that align with their own environmental values. Moreover, compliance with various international standards and regulations is critical, ensuring that suppliers not only meet quality expectations but also adhere to ethical practices that bolster their reputation in the market. As these trends continue to shape the industry, suppliers who adapt effectively will stand out as leaders in reliability and quality.

Top 10 DIN Standard Bearings Suppliers for Quality and Reliability

| Supplier Rank |

Quality Rating (1-10) |

Reliability Score (1-100) |

Market Share (%) |

Innovation Index (1-5) |

Geographical Reach |

| 1 |

9 |

95 |

25 |

4 |

Global |

| 2 |

8 |

90 |

20 |

3 |

Continental |

| 3 |

7 |

85 |

18 |

3 |

Europe |

| 4 |

6 |

80 |

15 |

2 |

Asia |

| 5 |

8 |

88 |

10 |

4 |

Global |

| 6 |

7 |

85 |

12 |

3 |

North America |

| 7 |

9 |

92 |

8 |

5 |

Global |

| 8 |

5 |

78 |

7 |

2 |

South America |

| 9 |

8 |

89 |

6 |

4 |

Asia |

| 10 |

6 |

82 |

5 |

2 |

Europe |

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us