9 Ways to Maximize Bearing Life with Innovative Extension Solutions

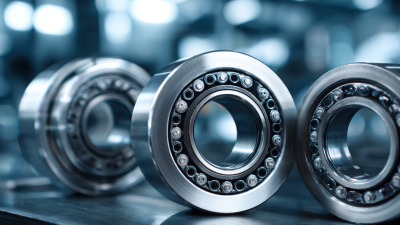

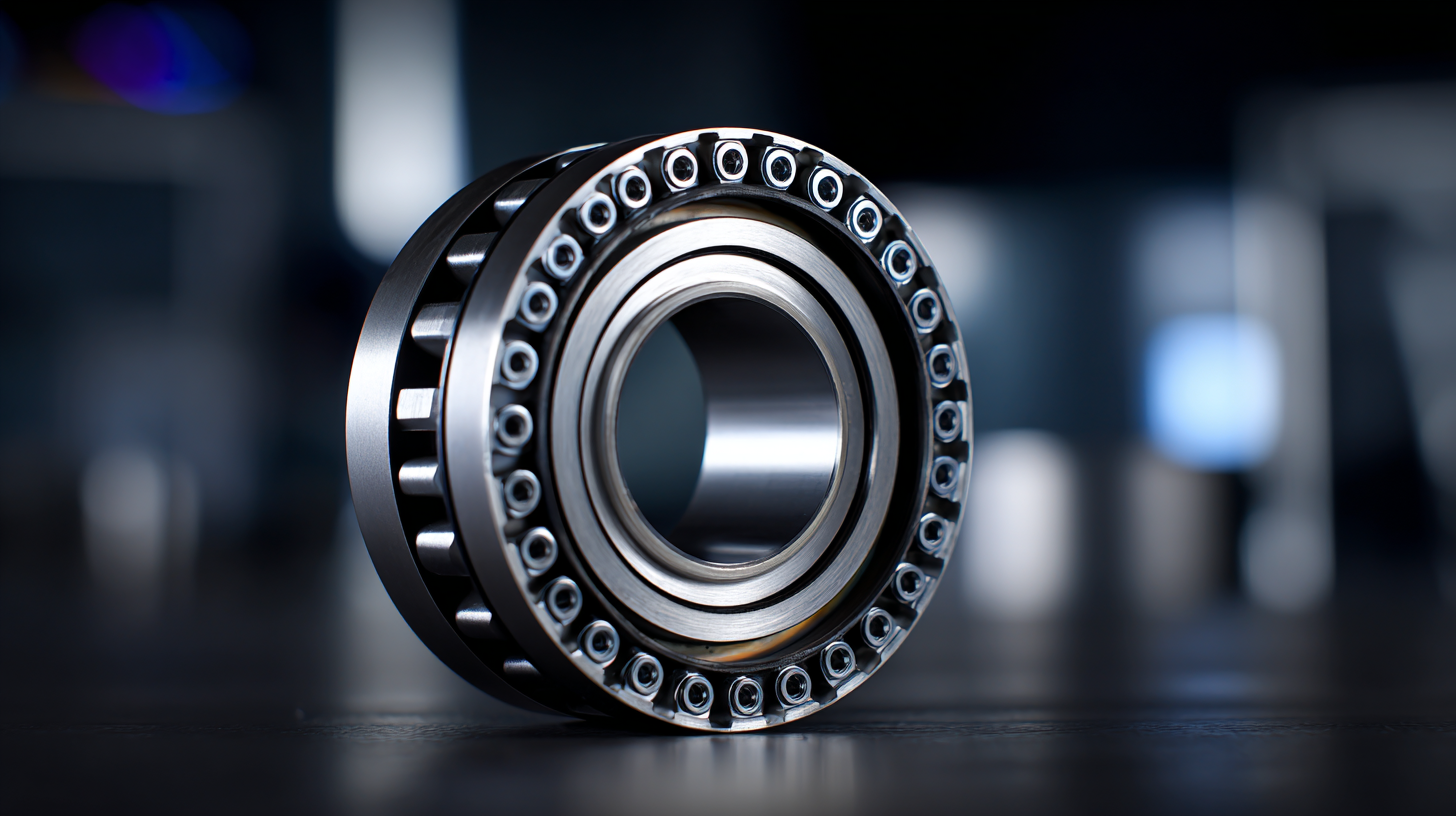

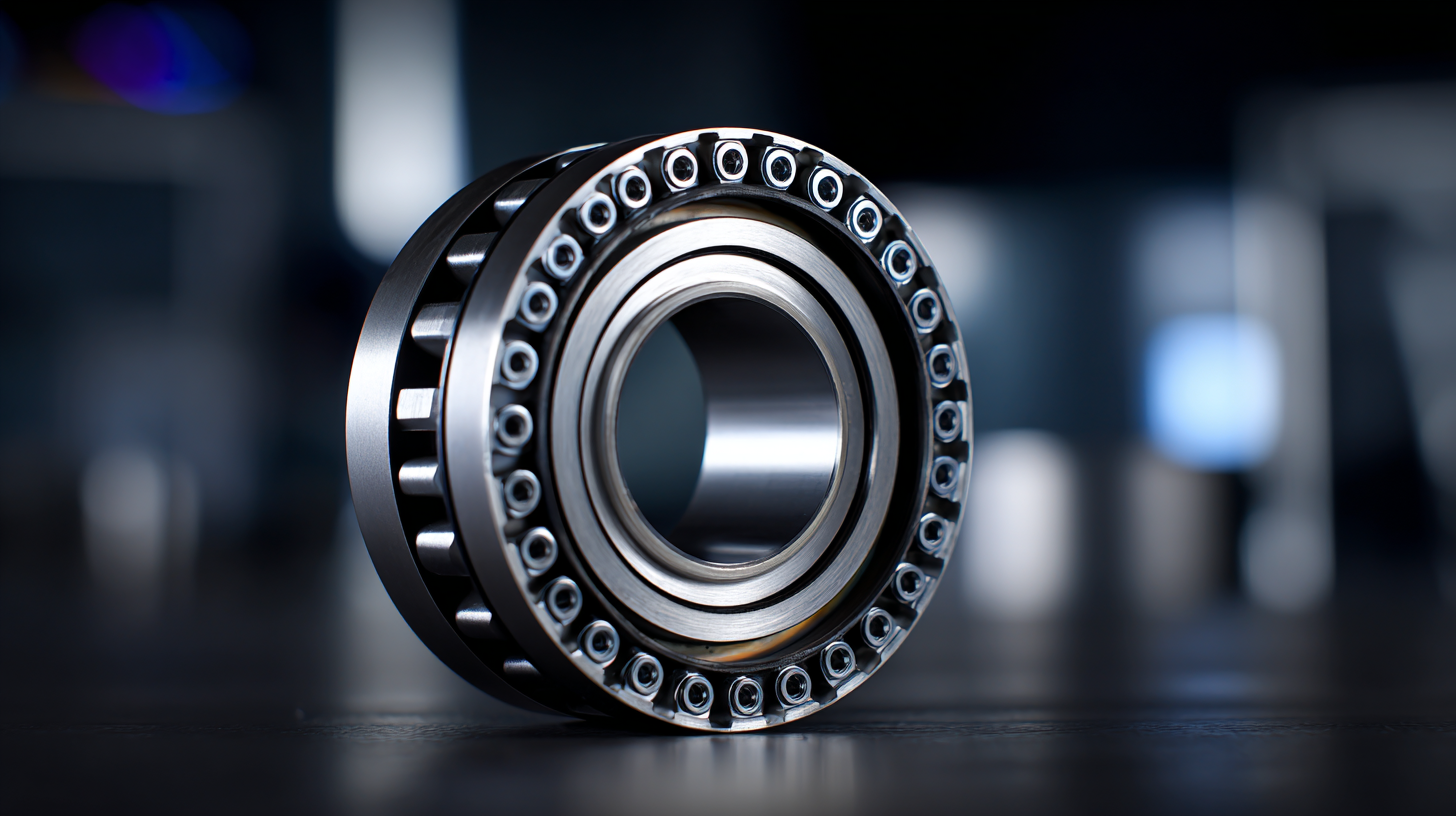

In the realm of industrial machinery, the longevity of bearings is critical for optimal performance and reduced downtime. According to recent market analyses, improper bearing maintenance is responsible for nearly 40% of machinery failures, leading to significant financial losses for manufacturers. Innovative Bearing Life Extension Solutions have emerged as a vital strategy to enhance the durability and reliability of these components. By implementing advanced technologies and best practices, companies can effectively increase bearing lifespan by up to 50%, minimizing operational costs and maximizing productivity. As the industry strives towards higher efficiency and sustainability, understanding and applying these solutions becomes essential for competitive advantage. The focus on maximizing bearing life not only reinforces operational integrity but also aligns with broader goals of resource optimization and cost management in modern manufacturing environments.

Innovative Maintenance Techniques to Enhance Bearing Longevity

Innovative maintenance techniques play a crucial role in enhancing the longevity of bearings, ensuring smooth operations in various applications. By adopting advanced materials and construction practices, companies can significantly improve the durability of their bearing systems. For instance, incorporating smart materials and nanomaterials can provide superior resistance to wear, corrosion, and fatigue, thereby extending the operational life of bearings.

Tips: Regular lubrication and proper sealing are essential to maintain the integrity of bearings. Use high-quality lubricants designed for specific operating conditions to minimize friction and wear. Additionally, implementing predictive maintenance strategies can empower engineers to monitor bearing conditions and identify potential failures early, allowing for timely interventions.

Emerging trends indicate a growing emphasis on sustainable practices, which can be integrated into bearing maintenance as well. Utilizing eco-friendly materials and methods not only promotes sustainability but can also enhance performance and reliability. Companies should invest in training and resources that focus on these innovative techniques, ultimately leading to improved bearing longevity and operational efficiency.

Advanced Lubrication Strategies for Extended Bearing Performance

Advanced lubrication strategies play a crucial role in extending bearing performance and overall machinery lifespan. According to a report from the Machinery Lubrication Industry, improper lubrication is responsible for up to 36% of premature bearing failures. By utilizing high-quality lubricants that are formulated specifically for the operating conditions, such as temperature and load, companies can significantly reduce wear and prolong bearing life. For instance, synthetic lubricants can withstand harsher environments than conventional oils, providing better protection against degradation and contamination.

Moreover, implementing effective lubrication methods such as automatic lubrication systems can enhance maintenance efficiency. A survey conducted by the International Society of Automation indicated that automatic lubrication can lead to a 50% reduction in lubrication-related failures, as it ensures consistent application of the right amount of lubricant over time. Regular monitoring of lubricant condition is also essential; studies show that proper lubricant analysis can increase bearing life by up to 30%. Incorporating these advanced lubrication strategies not only optimizes bearing performance but also contributes to significant cost savings in maintenance and downtime.

9 Ways to Maximize Bearing Life with Innovative Extension Solutions

| Strategy |

Description |

Expected Benefit |

Implementation Complexity |

| Regular Lubrication |

Frequent application of high-quality lubricants to reduce friction. |

Increased bearing lifespan and reduced wear. |

Low |

| Temperature Control |

Implement cooling systems to maintain optimal operating temperatures. |

Prevention of thermal degradation and enhanced performance. |

Medium |

| Vibration Monitoring |

Use sensors to monitor vibrations and detect misalignment or wear. |

Early detection of issues, extending bearing life. |

High |

| Proper Installation |

Ensure correct installation techniques to avoid undue stress. |

Reduction in premature failures due to installation errors. |

Low |

| Cleanliness Practices |

Keep the work area and components clean to prevent contamination. |

Minimized risk of damage from dirt and debris. |

Low |

| Quality Materials |

Select high-grade materials for bearings and components. |

Enhanced durability and performance. |

Medium |

| Load Management |

Avoid overload conditions to limit stress on bearings. |

Extended operational lifetimes and reliability. |

Medium |

| Regular Inspections |

Conduct routine checks to identify wear and potential failure points. |

Proactive maintenance extends life and performance. |

Low |

| Upgrade Technology |

Invest in advanced lubrication and monitoring technologies. |

Optimized performance leading to substantial savings and longer life. |

High |

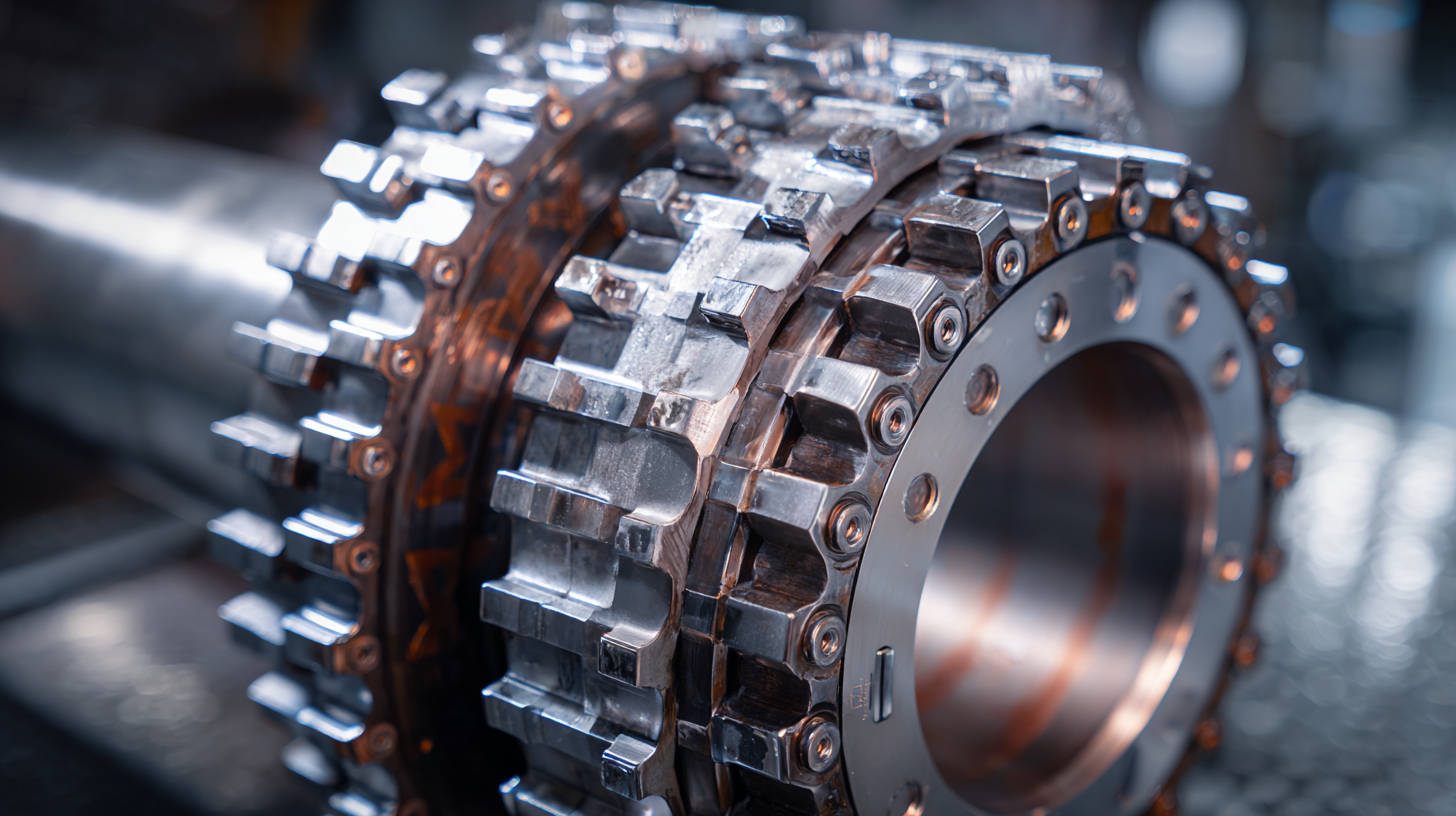

Cutting-Edge Materials: Utilizing Technology to Increase Bearing Durability

Innovative approaches in bearing technology have

revolutionized the industry, particularly through the development of cutting-edge materials aimed at

enhancing bearing durability. Advanced composites and

high-performance polymers have emerged as viable alternatives to

traditional materials, effectively resisting wear and fatigue. These modern materials demonstrate

superior resistance to heat and corrosion, significantly extending the operational lifespan of bearings

in various applications. The incorporation of these materials not only improves durability but also

reduces maintenance costs, providing a more efficient

solution for manufacturers.

Innovative approaches in bearing technology have

revolutionized the industry, particularly through the development of cutting-edge materials aimed at

enhancing bearing durability. Advanced composites and

high-performance polymers have emerged as viable alternatives to

traditional materials, effectively resisting wear and fatigue. These modern materials demonstrate

superior resistance to heat and corrosion, significantly extending the operational lifespan of bearings

in various applications. The incorporation of these materials not only improves durability but also

reduces maintenance costs, providing a more efficient

solution for manufacturers.

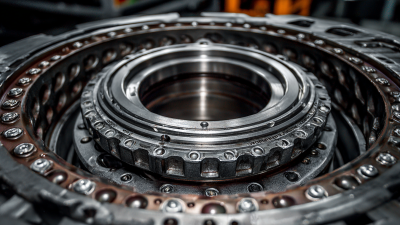

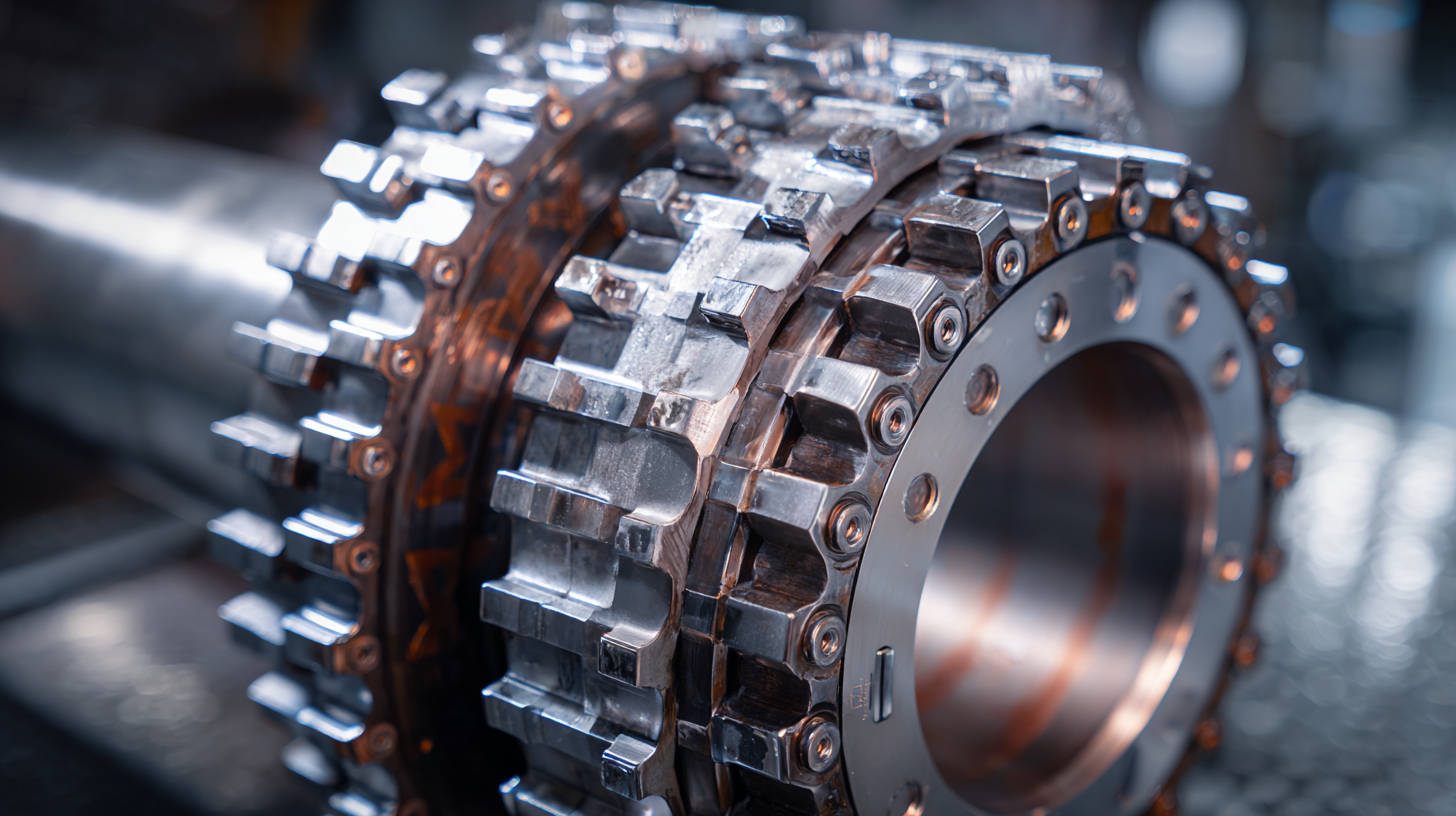

In addition to new material development, the integration of technology, such as smart sensors

and predictive analytics, further elevates the performance of bearings. By monitoring

conditions in real-time, companies can identify potential issues before they lead to catastrophic failures.

This proactive approach leverages cutting-edge technology to optimize the longevity of bearings, ensuring

they operate under ideal conditions. The combination of innovative materials with intelligent monitoring systems

illustrates a comprehensive strategy for maximizing bearing life and enhancing overall machine reliability in

the rapidly evolving industrial landscape.

Real-Time Monitoring Solutions for Proactive Bearing Care

Real-time monitoring solutions are revolutionizing the way industries approach bearing maintenance. By integrating advanced sensors and IoT technologies, companies can continuously track the health and performance of bearings. This proactive approach enables early detection of potential issues, allowing for timely interventions before they escalate into costly failures. Not only does this enhance the reliability of machinery, but it also significantly extends the operational life of bearings, maximizing overall productivity.

Furthermore, real-time data analytics can provide insights into usage patterns and operating conditions, facilitating more informed decision-making. Maintenance teams can shift from a reactive to a proactive strategy, scheduling maintenance only when necessary based on actual performance data rather than relying on outdated time-based schedules. This optimization not only saves costs associated with unnecessary inspections but also improves asset management and operational efficiency, ensuring that bearings operate at peak performance levels.

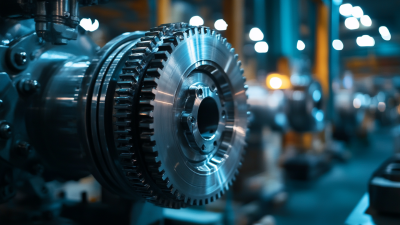

Design Innovations to Improve Bearing Installation and Alignment

Bearing performance is crucial for the longevity of machinery, and recent advancements in design innovations have significantly improved bearing installation and alignment processes. According to a report by the American Society of Mechanical Engineers (ASME), improperly installed bearings can reduce their lifespan by up to 50%. This emphasizes the necessity for precise alignment and installation techniques. Innovative solutions such as self-aligning bearings and modular mounting systems are increasingly being utilized to mitigate these issues, allowing for easier adjustments and reducing the risk of misalignment.

Additionally, a study conducted by the International Journal of Mechanical Engineering highlighted that utilizing advanced alignment tools can enhance the accuracy of bearing installation by up to 30%. These tools enable technicians to achieve near-perfect alignment, crucial for minimizing wear and extending the operational life of bearings. By implementing these design innovations, industries can significantly reduce maintenance costs and downtime, ultimately leading to increased operational efficiency. The focus on improving bearing installation and alignment not only enhances performance but also positions organizations to better meet the demands of modern machinery.

Maximizing Bearing Life: Impact of Installation Techniques

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Innovative approaches in

Innovative approaches in