How to Ensure Optimal Performance with Bearing Maintenance and After Sales Support

In today’s competitive industrial landscape, effective Bearing Maintenance & After-Sales Support is essential for maximizing equipment reliability and performance. According to a report by the International Organization for Standardization (ISO), poor maintenance practices can lead to failure rates that increase by up to 30%, significantly impacting operational efficiency and maintenance costs. Furthermore, market research indicates that industries implementing comprehensive maintenance strategies can reduce downtime by as much as 40%, translating to substantial financial savings and improved productivity. The importance of robust after-sales support cannot be overstated, as it ensures that businesses receive timely assistance and access to critical resources necessary for sustaining optimal performance. This guide will explore best practices and strategies for implementing effective bearing maintenance programs and leveraging after-sales support to enhance overall operational efficiency and reliability.

Understanding the Importance of Bearing Maintenance for Performance Optimization

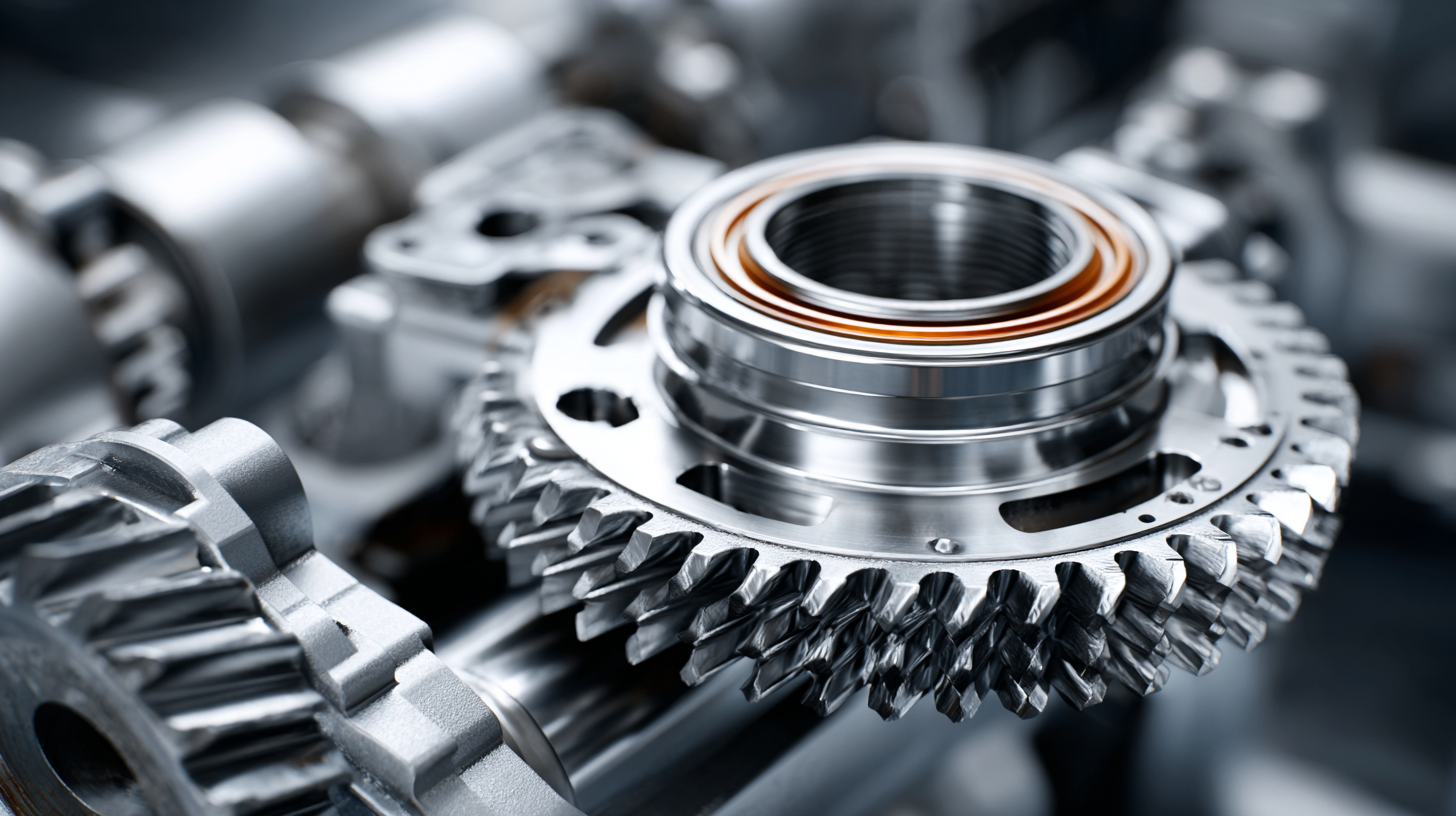

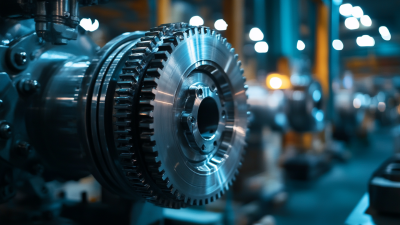

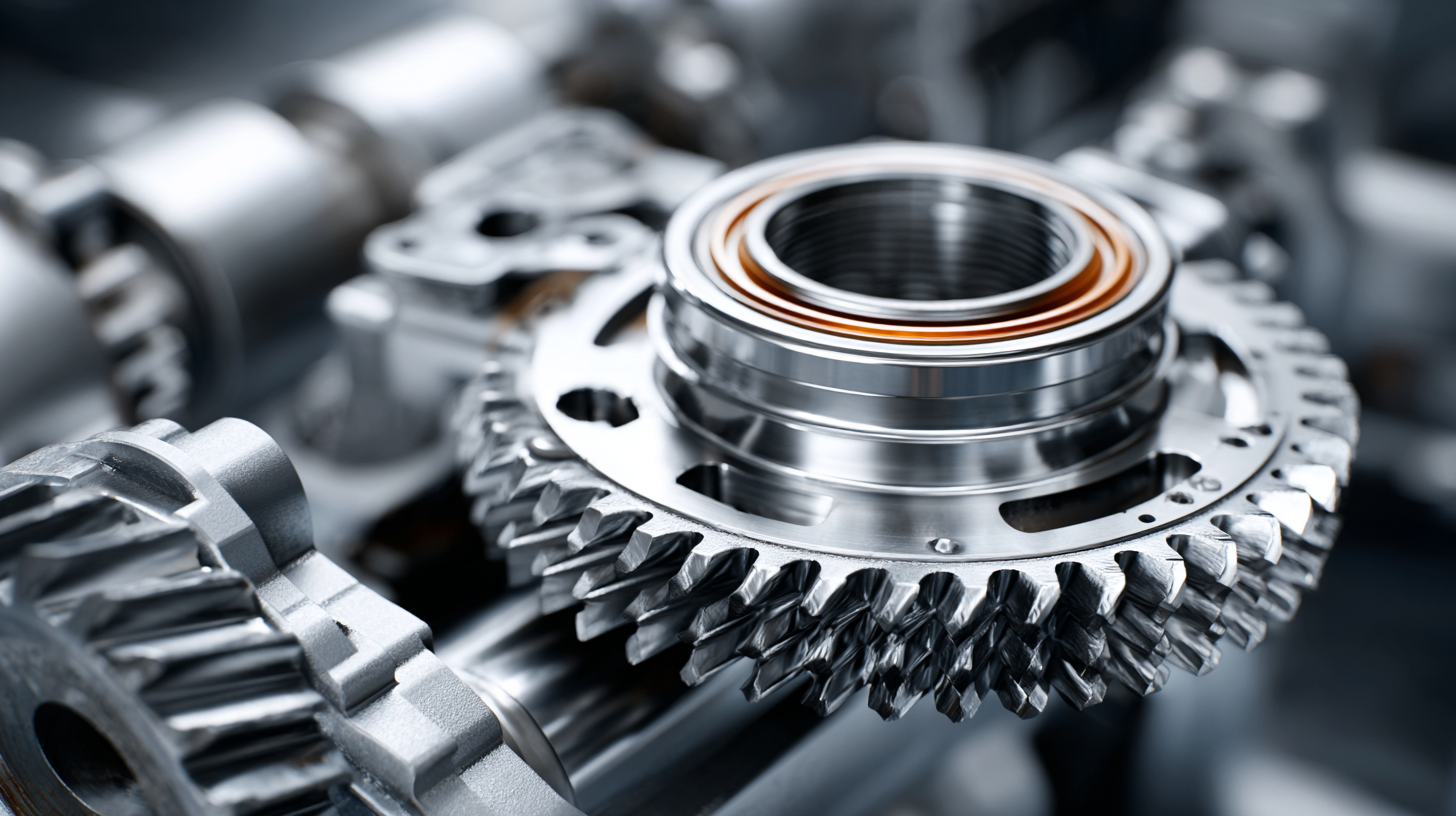

Bearing maintenance plays a crucial role in optimizing the performance of machinery and equipment. Properly maintained bearings ensure smooth operation, reduce friction, and prolong the lifespan of both the bearings themselves and the equipment they support. Regular inspections and maintenance routines can help identify wear or potential failures before they escalate into costly breakdowns, thereby minimizing downtime and maximizing productivity.

Furthermore, effective after-sales support complements maintenance efforts by providing users with the necessary resources and expertise to address any issues that arise. This includes access to technical guidance, spare parts, and troubleshooting assistance, which can significantly enhance the performance of bearings in demanding environments. By understanding the significance of both proactive maintenance and responsive support, operators can achieve optimal performance levels, translating into improved overall efficiency and reduced operational costs.

How to Ensure Optimal Performance with Bearing Maintenance and After Sales Support - Understanding the Importance of Bearing Maintenance for Performance Optimization

| Maintenance Activity |

Frequency |

Expected Lifespan (Years) |

Impact on Performance |

After Sales Support Options |

| Lubrication |

Every 6 months |

5-7 |

Improves friction reduction |

Regular check-ups |

| Inspection |

Annually |

3-5 |

Detects wear and tear early |

Emergency support hotline |

| Replacement |

As needed |

1-2 |

Restores original performance |

On-site installation support |

| Cleaning |

Every 3 months |

4-6 |

Enhances efficiency |

Training for maintenance staff |

Key Maintenance Practices to Extend Bearing Lifespan and Reliability

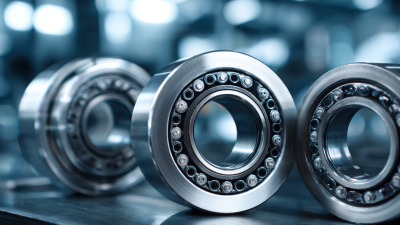

Proper bearing maintenance is essential for extending the lifespan and reliability of machinery. Research shows that effective maintenance practices can enhance bearing life by up to 30% (Source: SKF Engineering Consultancy). Regularly monitoring and maintaining bearings reduces the risk of unexpected failures, which can lead to costly downtime and repairs. Key practices include regular lubrication, contamination control, and temperature monitoring. Lubrication, in particular, is critical, as insufficient lubrication is a leading cause of bearing failures. According to the Noria Corporation, approximately 50% of bearing failures are due to improper lubrication.

Proper bearing maintenance is essential for extending the lifespan and reliability of machinery. Research shows that effective maintenance practices can enhance bearing life by up to 30% (Source: SKF Engineering Consultancy). Regularly monitoring and maintaining bearings reduces the risk of unexpected failures, which can lead to costly downtime and repairs. Key practices include regular lubrication, contamination control, and temperature monitoring. Lubrication, in particular, is critical, as insufficient lubrication is a leading cause of bearing failures. According to the Noria Corporation, approximately 50% of bearing failures are due to improper lubrication.

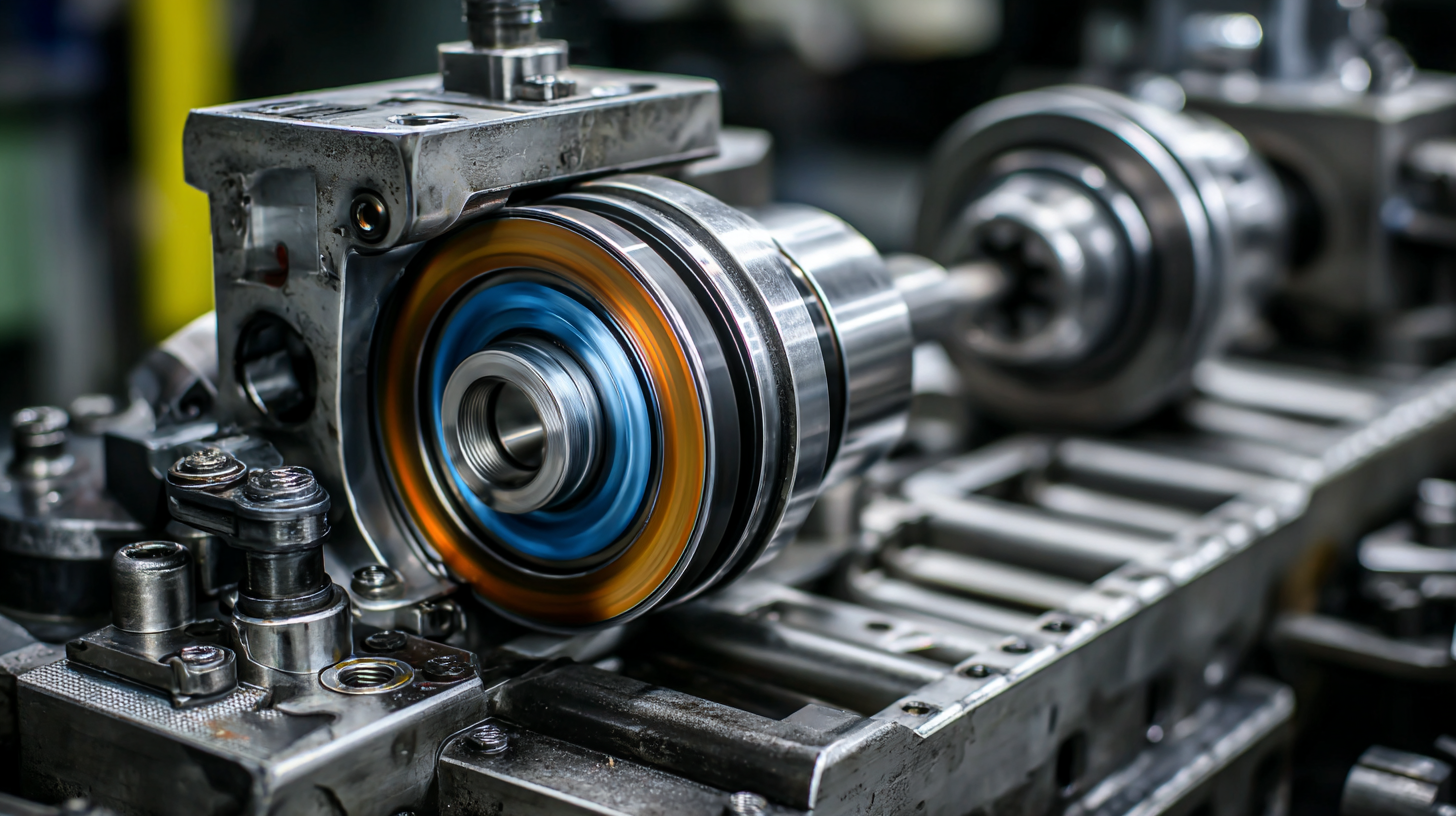

Another vital aspect of bearing maintenance is regular inspections and monitoring. Utilizing advanced technologies, such as condition monitoring systems, allows for real-time assessment of bearing performance. Sensors can detect changes in vibration, temperature, and acoustic emissions, offering insights into potential issues before they escalate. A report from the International Journal of Mechanical Engineering reveals that predictive maintenance strategies can save companies up to 20% in maintenance costs while improving asset uptime and reliability. By implementing these best practices, organizations can ensure optimal performance and significantly extend the life of their bearings.

Implementing Effective After Sales Support for Continuous Performance Monitoring

Effective after-sales support is crucial for continuous performance monitoring of bearings, as it directly affects both the longevity and reliability of the equipment. After a sale, the relationship between the supplier and customer should evolve into a partnership focused on maximizing the operational efficiency of the bearings. This includes regular follow-ups and technical support, where the suppliers offer guidance on optimal usage, troubleshooting, and maintenance practices. By providing customers with the necessary resources and insights, suppliers can help ensure that the bearings operate at their best throughout their lifecycle.

Additionally, establishing a robust feedback mechanism is essential for continuous performance monitoring. Suppliers should encourage customers to share their experiences and any issues they encounter, enabling them to address concerns proactively. Regular performance evaluations and assessments can be offered as part of the after-sales service, helping to identify potential problems before they escalate. With a focus on proactive communication and support, suppliers not only enhance customer satisfaction but also contribute to improved performance and reduced downtime for the equipment relying on these bearings.

Identifying Common Bearing Issues and Proactive Solutions for Maintenance

Ensuring optimal performance in bearing maintenance is essential for minimizing downtime and enhancing productivity in various industries. Common bearing issues, such as misalignment, contamination, and inadequate lubrication, can lead to significant operational inefficiencies. A study by the International Journal of Engineering Research indicates that proper maintenance can reduce equipment failures by up to 30%. Identifying these issues proactively allows companies to implement effective strategies, including regular inspections and condition monitoring, which can extend bearing life and improve overall machinery performance.

Data science plays a crucial role in revolutionising maintenance practices within industries such as textiles. By leveraging data analytics, manufacturers can forecast potential bearing failures, enabling predictive maintenance rather than reactive fixes. Research conducted by industry experts shows that predictive maintenance can lead to a 10-20% reduction in maintenance costs. Furthermore, integrating machine learning algorithms can help identify patterns that signal impending issues, thus allowing for timely interventions that prevent costly downtimes. This proactive approach not only enhances operational efficiency but also supports sustainable practices by reducing waste and energy consumption in manufacturing processes.

Leveraging Technology in Bearing Maintenance for Improved Efficiency and Support

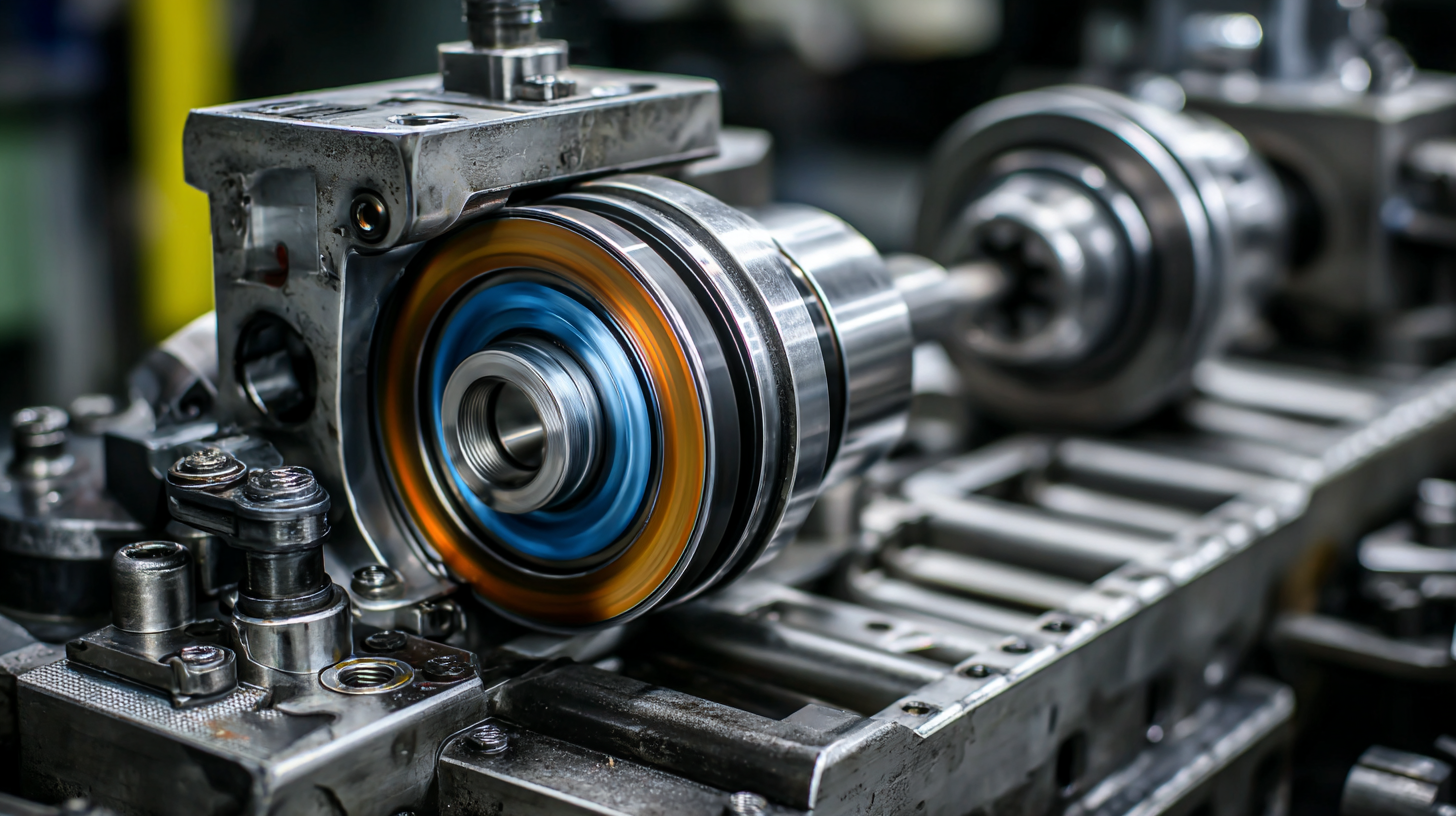

Leveraging technology in bearing maintenance has become crucial for enhancing efficiency and ensuring optimal performance. The vacuum preloaded air bearing market, driven by applications in semiconductor manufacturing and precision machining, is expected to grow significantly. With the adoption of advanced technologies, companies are developing innovative solutions that reduce energy consumption while maintaining superior cooling capacities. For instance, a recent development in air-cooled magnetic bearings promises a remarkable 40% reduction in energy use, thereby setting a new standard for performance in its sector.

Furthermore, the introduction of predictive maintenance techniques in motor and transmission systems signifies a shift toward more proactive management practices. The use of vibration sensors, which are essential for monitoring the oscillatory movements of machinery, has gained traction. These sensors are integral for predictive maintenance strategies not only in motors but also in bearings, pumps, and turbines. By employing these technologies, companies can enhance their operational efficiency and extend the lifespan of critical components, ultimately contributing to improved after-sales support and customer satisfaction in the bearing industry.

Bearing Maintenance Efficiency Overview

This chart illustrates the correlation between the frequency of bearing maintenance and the reported efficiency percentages. Regular maintenance schedules tend to maintain higher efficiency levels, showcasing the importance of consistent maintenance practices.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us

Proper bearing maintenance is essential for extending the lifespan and reliability of machinery. Research shows that effective maintenance practices can enhance bearing life by up to 30% (Source: SKF Engineering Consultancy). Regularly monitoring and maintaining bearings reduces the risk of unexpected failures, which can lead to costly downtime and repairs. Key practices include regular lubrication, contamination control, and temperature monitoring. Lubrication, in particular, is critical, as insufficient lubrication is a leading cause of bearing failures. According to the Noria Corporation, approximately 50% of bearing failures are due to improper lubrication.

Proper bearing maintenance is essential for extending the lifespan and reliability of machinery. Research shows that effective maintenance practices can enhance bearing life by up to 30% (Source: SKF Engineering Consultancy). Regularly monitoring and maintaining bearings reduces the risk of unexpected failures, which can lead to costly downtime and repairs. Key practices include regular lubrication, contamination control, and temperature monitoring. Lubrication, in particular, is critical, as insufficient lubrication is a leading cause of bearing failures. According to the Noria Corporation, approximately 50% of bearing failures are due to improper lubrication.