Top 2025 Automation Equipment Bearing Solutions for Increased Productivity

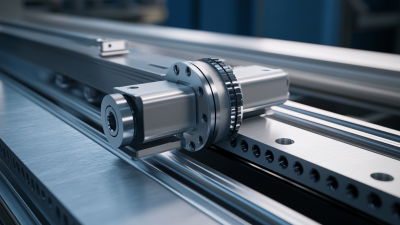

In today's rapidly evolving industrial landscape, the demand for enhanced efficiency and productivity is greater than ever. As manufacturers strive to optimize their operations, the role of automation has become increasingly vital. One pivotal component of this automation revolution is the development of advanced automation equipment bearing solutions. These solutions not only streamline processes but also improve the reliability and longevity of machinery, thereby reducing downtime and maintenance costs.

As we look towards 2025, it's clear that the integration of innovative bearing technologies will play a crucial role in transforming manufacturing and production capabilities. By focusing on automation equipment bearing solutions, companies can harness the power of cutting-edge designs and materials, enabling them to meet the growing demands of their respective industries. This shift not only enhances production rates but also supports sustainability initiatives by maximizing resource efficiency.

In this exploration of top automation equipment bearing solutions for increased productivity, we will delve into the emerging trends, technologies, and best practices that are shaping the future of manufacturing. By adopting these advanced solutions, businesses can position themselves at the forefront of the automation revolution, ensuring they remain competitive in an ever-changing marketplace.

Top Trends in Automation Equipment Bearings for 2025

As the automation industry continues to evolve, the demand for advanced bearing solutions is set to significantly increase by 2025. Key trends indicate that manufacturers are focusing on high-performance materials and innovative designs to improve the efficiency and reliability of automation equipment. According to a recent market analysis by Research and Markets, the global bearings market is projected to reach approximately $80 billion by 2025, largely driven by the surging demand for automated systems across various sectors, including manufacturing and logistics.

One of the pivotal trends in bearing technology is the adoption of smart bearings integrated with IoT capabilities. These innovative solutions allow for real-time monitoring and predictive maintenance, significantly reducing downtime and maintenance costs. A report by MarketsandMarkets anticipates that the market for IoT-enabled bearings will grow from $1.2 billion in 2020 to over $4 billion by 2025, demonstrating the increasing importance of data-driven solutions in enhancing productivity and operational efficiency in automation.

Additionally, the trend towards sustainability is influencing bearing design, with a growing emphasis on energy-efficient products and recycled materials. The ongoing shift in manufacturing practices is driving engineers to explore hybrids and ceramic bearing options, which not only offer improved performance in harsh environments but also align with green manufacturing initiatives. As industries strive to minimize their environmental impact, the push for bearing solutions that contribute to overall sustainability is expected to intensify in the coming years.

Innovative Materials Driving Bearing Performance in Automation

The automation industry is rapidly evolving, with 2025 poised to witness significant advancements in bearing solutions that enhance productivity. Central to this progress is the adoption of innovative materials that improve bearing performance across various applications. According to a recent market analysis, the global market for bearing materials is projected to grow at a CAGR of 7.5% from 2021 to 2026, driven largely by the demand for lightweight, high-strength alternatives that can withstand the rigorous demands of automated systems.

Modern bearings are increasingly being manufactured from advanced composites, ceramics, and high-performance polymers. These materials not only offer superior wear resistance and reduced friction but also contribute to longer service life, which is critical in high-speed and high-load applications. A report from the International Federation of Robotics notes that by 2025, the integration of automation technologies across industries could lead to efficiency gains of up to 30%, largely due to enhanced components such as bearings that minimize downtime and maintenance costs.

With sustainability becoming a key focus, many manufacturers are also exploring eco-friendly materials that reduce environmental impact without compromising performance. These innovative materials facilitate energy savings and lower rolling resistance in bearings, which is crucial in energy-intensive operations. Industry experts predict that the shift towards sustainable bearing solutions will also align with broader trends in automation, positioning companies to not only meet productivity goals but also adhere to environmental standards.

Market Demand: Statistics on Automation Equipment and Bearing Growth

The demand for automation equipment and bearing solutions has been steadily rising as industries seek to enhance productivity and efficiency. Recent statistics indicate a significant growth trajectory for these sectors, driven by advancements in technology and a shift toward automation in manufacturing processes. The global market for automation equipment is projected to expand, with a particular emphasis on integrating intelligent systems that reduce downtime and improve operational reliability.

As businesses adopt more automated systems, the need for high-performance bearing solutions becomes increasingly critical. Bearings play a vital role in minimizing friction and wear, ensuring smooth operation of machinery. According to market reports, the bearing industry is expected to experience robust growth as manufacturers invest in improved designs and materials that accommodate higher speeds and loads while maintaining efficiency. The interplay between automation equipment and bearing innovations is crucial in meeting the modern demands of production environments, ultimately leading to enhanced productivity across multiple sectors.

Impact of Advanced Bearing Solutions on Operational Efficiency

The operational efficiency of any automated system relies heavily on the quality and performance of its bearing solutions. Advanced bearing technologies have significantly evolved over recent years, introducing materials and designs that minimize friction, enhance load-carrying capacity, and extend service life. These improvements lead to reduced downtime, smoother operations, and ultimately, higher productivity levels. By implementing such innovative bearing solutions, organizations can achieve a more streamlined workflow, reducing energy consumption and maintenance costs while maximizing output.

Furthermore, the integration of smart bearings, equipped with sensors and monitoring capabilities, can greatly impact performance optimization. These intelligent systems provide real-time data on operational conditions, allowing for proactive maintenance and immediate responses to potential issues. This connectivity fosters a culture of predictive maintenance, reducing the frequency of unexpected breakdowns and enhancing overall reliability. The strategic adoption of such advanced bearing solutions not only boosts operational efficiency but also supports a sustainable approach to automation by lowering resource wastage and improving asset longevity. As industries gear up for the challenges of 2025, investing in high-performance bearing solutions will be pivotal for achieving enhanced productivity and competitiveness.

Top 2025 Automation Equipment Bearing Solutions for Increased Productivity

| Bearing Type |

Material |

Load Capacity (kg) |

Speed Rating (rpm) |

Application |

Impact on Efficiency (%) |

| Angular Contact Ball Bearing |

Steel |

5000 |

12000 |

Robotics |

15 |

| Deep Groove Ball Bearing |

Ceramic |

4000 |

15000 |

CNC Machines |

20 |

| Self-Aligning Ball Bearing |

Stainless Steel |

3000 |

8000 |

Conveyor Systems |

10 |

| Thrust Ball Bearing |

Bronze |

2000 |

5000 |

Heavy Machinery |

12 |

Future Challenges and Opportunities in Bearing Technologies for Automation

The future of bearing technologies in the automation sector is defined by both challenges and opportunities that stakeholders must navigate to enhance productivity. The advent of smart manufacturing and Industry 4.0 has ushered in a need for bearings that not only reduce friction but also integrate with IoT systems for real-time monitoring and predictive maintenance. According to a report by Research and Markets, the global bearing market is expected to reach $169.5 billion by 2025, driven by the demand for high-performance bearings in automated applications. As industries increasingly embrace automation, there is a growing emphasis on the durability and reliability of bearing solutions, particularly under conditions of high load and varying operational speeds.

As automation technologies evolve, companies face challenges in the form of materials science and the need for advanced lubrication systems. Recent insights from the International Bearing Industry Association highlight that more than 20% of bearing failures can be attributed to inadequate lubrication. This indicates a significant opportunity for innovation in lubrication technology that could enhance bearing life and reduce overall maintenance costs. Moreover, the trend towards miniaturization presents another challenge—designing compact bearings that maintain high performance without compromising on load capacity or lifespan is crucial. This intersection of demand and innovation underlines the importance of developing next-generation bearing solutions that not only meet the specifications of modern automation systems but also anticipate future needs in productivity and efficiency.

Home

Products

Industrial Bearings

Deep Groove Ball Bearings

Self-Aligning Ball Bearings

Angular Contact Ball Bearings

Cylindrical Roller Bearings

Taper Roller Bearings

Spherical Roller Bearings

Bearing housing or Accessories

Miniature Bearing

Thrust ball bearing

Radial Spherical Plain Bearing

Pillow Block Bearing

Needle Roller Bearings

Automotive Bearings

Agricultural Bearings

Special Material Bearings

Industry Application

About Us

News

Contact Us